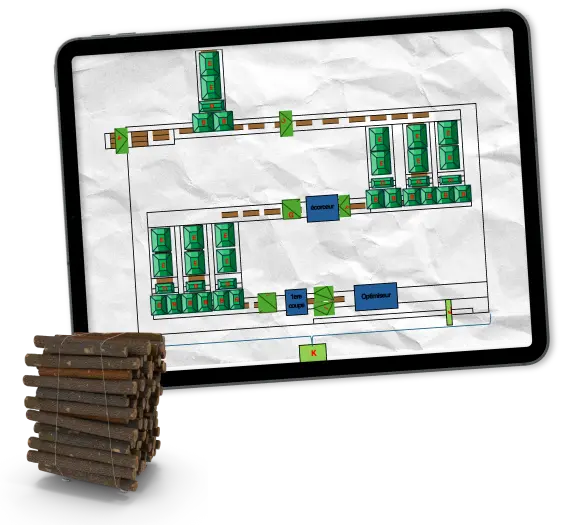

Our AI-powered industrial vision systems can accurately assess the volume, species, and quality of wood in inventory. By automatically tracking and categorizing wood stock, manufacturers can optimize inventory levels, reduce stockouts and overstock situations, and ensure timely replenishment. This improves overall inventory management efficiency and reduces the risk of material shortages or excesses.